VISTA is a measuring system for detecting defects and other features on transparent or highly reflective surfaces. So far, the technology “made in Salzburg” has been used in the ophthalmic lens industry. Spectacle lenses can be inspected and classified fully automatically, and the results are automatically documented. “However, the areas of application are versatile. From foils to ski goggles to window panes, everything is possible. Basically, we can work with anything that is transparent. Sample carriers in medical technology are also conceivable, for example. We are also still looking for partners who would like to use our technology for various applications,” says Michael Göbl. Anyone who would like to get in touch is welcome to contact him at michael.goebl@auc.systems.

In the right place at the right time

How does one actually come up with such an idea? “By chance, through a holiday acquaintance of our former owner Leo Stadlmayr, who unfortunately passed away two years ago. He met a manufacturer of spectacle lenses on a trip. He told us that spectacle lenses are still checked manually. Our research confirmed this,” says Michael Göbl. On an average production line, about 6,000 lenses are produced per day and each of them has to be taken by hand and checked for cosmetic defects such as scratches or dust inclusions. The optical properties that correct the defective vision can already be checked by machine. And so they came up with the idea of also developing an automation solution for cosmetic inspection.

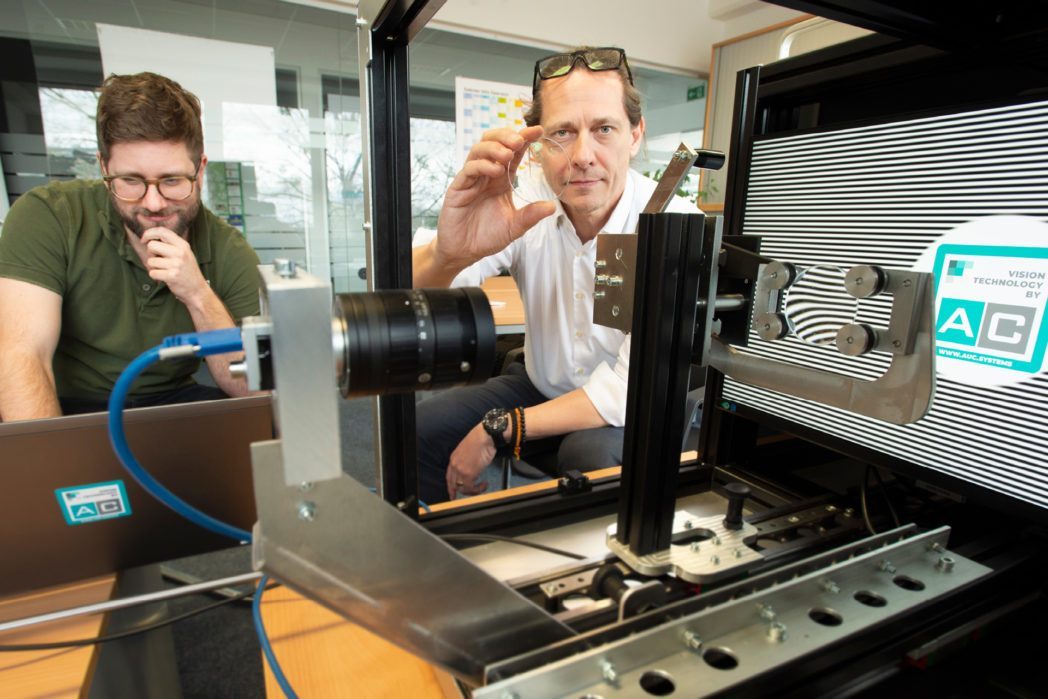

“In January 2020, this idea came to me via our owner. We have already worked with various camera systems in the past. We thought that these could certainly also be used for spectacle lenses,” says Michael Göbl about the concretisation of VISTA. “Then we happened to read an article in the German Handelsblatt about the TU Braunschweig, which dealt with a similar topic. After a few tests, we got in touch with the university,” Göbl continues. So we started a series of tests with the TU Braunschweig, which confirmed that machine inspection on transparent objects is possible with cameras for surface inspection. The technology used (deflectometry) was originally developed for measuring highly reflective three-dimensional bodies. The adaptation of the measurement setup from reflection to transparency enables the detection of defects on the transparent medium glass.

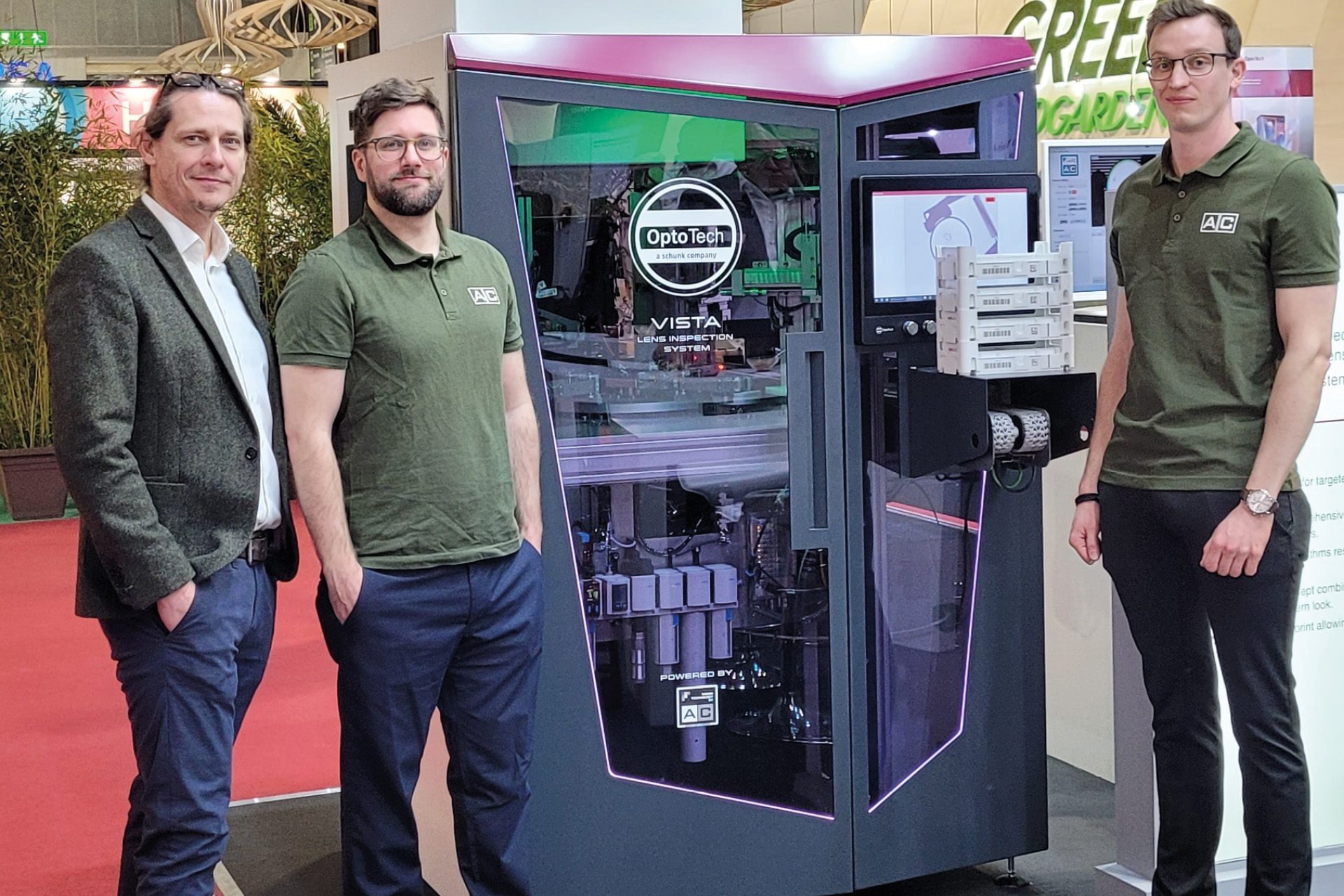

“To develop a software application that is suitable for series production and high performance, we set up a small R&D department in-house,” Göbl reports. “In 2020, we started looking at the topic. In 2021, we were then ready to start development. And in 2022, we were finally able to set up the first prototype at a Swiss spectacle lens manufacturer. Here, we quickly achieved good results, finding close to 100 per cent of cosmetic defects,” Göbl continues. “In 2023, we were able to present VISTA to the professional audience at the MIDO international trade fair in Milan and were awarded the Salzburg WIKARUS business prize in the ‘Innovation’ category.”

Superior to the human eye

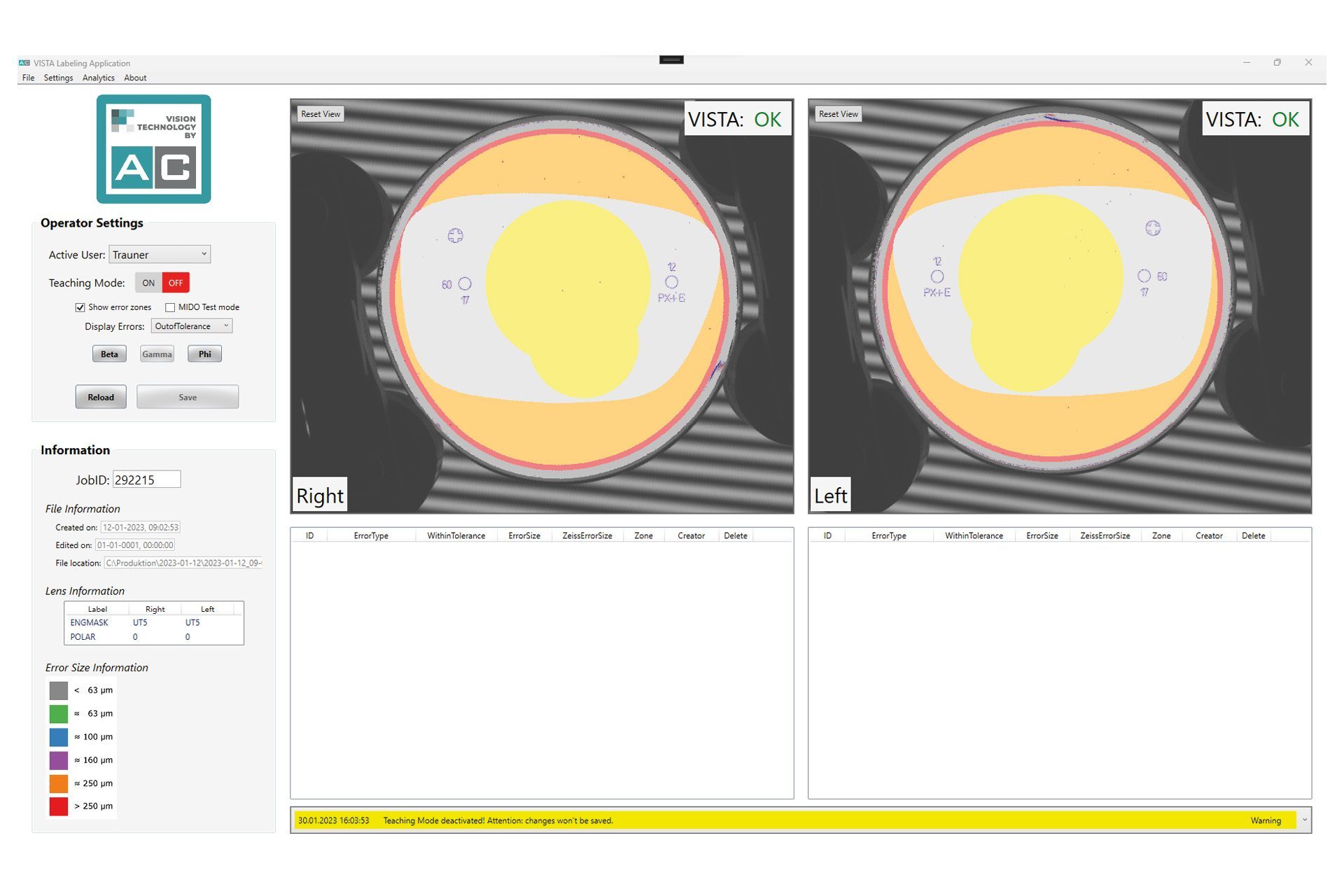

About ten per cent of the lenses produced have defects. A&C’s machine can find defects larger than 20 microns. The previously accepted threshold for a defect is > 63 micrometres. “Our Swiss partner now has VISTA take over the quality control completely and only lenses that are qualified as defective are additionally checked by specialist personnel. In a next step, the lenses of the production line will be tested and classified exclusively by VISTA. The performance of the measuring system is equivalent to finding a 10 cent coin on a football field within 6 seconds. Contrary to specialists who check manually, VISTA does not tire. However, from the beginning we have made sure that we learn from the manual inspectors – the majority of whom are women. In the meantime, we are discovering errors that they have not seen. VISTA now ‘sees’ more in the given time than the trained human eye,” says Michael Göbl.S

All-round protection for brand and IP

A&C supplies automation solutions for plant construction and industrial production operations. The service company plans and programmes control systems for various industries – from the paper industry and cement plants to cereal bar producers and breweries. For its global success, the SME was awarded the Austrian Bronze Export Prize in 2023. “The idea and desire to create our own product from our services has been around for decades,” reports Managing Director Michael Göbl. With VISTA, this project could now be realised.

A new product must be protected at an early stage. For this reason, A&C was supported by the team of the Service Centre Innovation in applying for EU trademark funding, including the registration of an international trademark. Together with experts from the aws and the patent office, an IP analysis was carried out (Discover.IP). Assistance was also provided in initiating technology transfer with national and international companies. As far as funding is concerned, it was possible to take advantage of an FFG project (basic funding). “Through Romana Schwab’s efforts, we also came across the EEN platform,” says Michael Göbl.

About A&C Automationssysteme und Consulting GmbH

- Salzburg City

- 14 employees in Salzburg, 6 in Zagreb

- SME

- Technical office in the field of industrial plant automation with services in consulting, hardware and software engineering, turnkey, projects and networks.

- auc.systems/vista

This might also interest you

6. March 2025

salz21: Necessary Steps for the Future

On March 5, 2025, salz21 | Home of Innovation once again provided a platform for future topics, innovations, and interdisciplinary exchange. More than 1,000 visitors took the opportunity to learn about current developments and discuss perspectives for tomorrow. Three topics were particularly dominant: climate protection, artificial intelligence, and a strong Europe.

25. September 2024

Green Deal: How Sustainable Business Development Can Look

The EU aims to create political and legal frameworks through the Green Deal to transform both the economy and society in a sustainable way. The Pinzgau-based company Design Composite demonstrates how this can be implemented.

15. August 2024

Sunbeam Yachts: Where Craftsmanship Meets Digitalization

Sunbeam Yachts has been building exclusive sailing yachts at Mattsee for generations. The production is done by hand, with some processes now digitally supported.

12. August 2024

SBS: One Software for Many Self-Service Devices

As a leading provider of banking software in Salzburg, SBS is now exploring new markets. The company remains true to its core segment by offering manufacturer-neutral software for self-service devices in additional sectors.