The first step towards more digitalisation in production began with an analysis process to identify potential improvements in the production workflow. For this, design composite was able to make use of the “Coaching” funding from the state of Salzburg.

More Transparency through New Systems

Building on this, a custom production software tailored to in-house needs was developed in collaboration with a software partner, which was also integrated with a new ERP system. This now allows all production processes to be monitored in real time. All employees have access to all necessary information, such as production orders, plans, work instructions, etc., via tablets/PCs at any time. This has increased transparency and confirmed many positive effects: The effort and potential sources of error during handovers have been reduced, customers can receive information about the progress of orders at any time, and because processes were improved and problem areas verified, efficiency could be significantly increased and costs reduced. Lastly, real-time insight into material availability enabled digital production planning and thus increased production capacities.

The Right Funding

“Support from the consultants at Innovation Salzburg was extremely valuable for us in all these projects,” explains Johann Aster, Sales Manager at design composite. “This allowed us to apply for the right funding for every step of the process and thus jointly manage large investments.” This includes the resources needed for software, programming, human resources, and equipment, which were supported by the state funding Salzburg.Digital (specifically Digi-Invest) in this case.

About design composite

- Headquarters: Niedernsill

- 30 employees

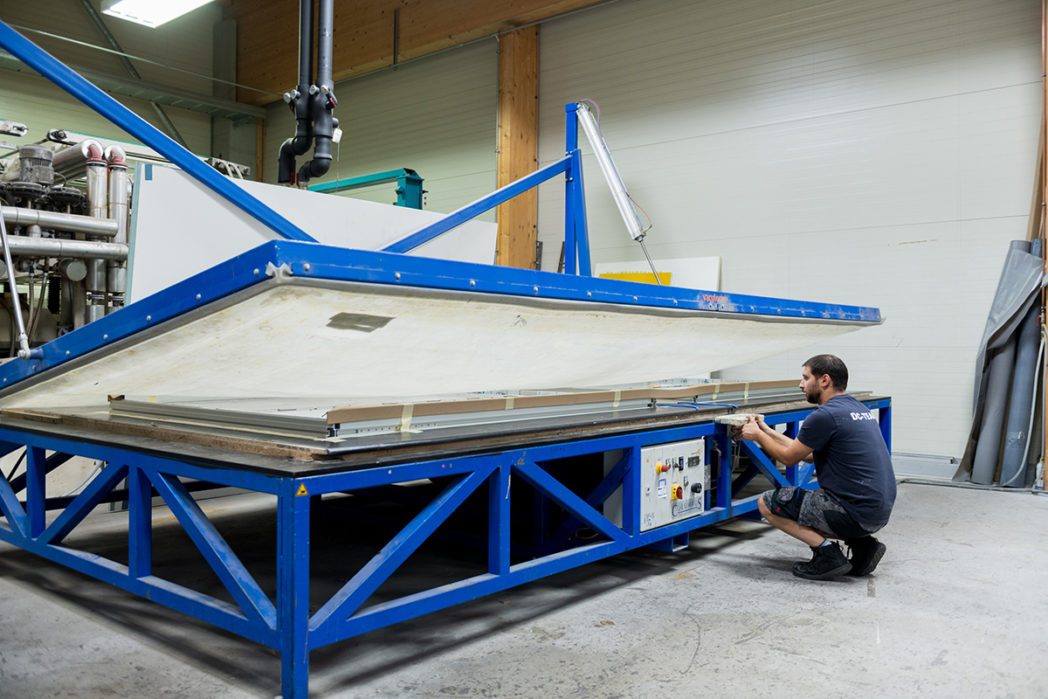

- Manufacturing of composite panels for commercial vehicles, industry, and construction, as well as architectural panels as design elements

- www.design-composite.com

This might also interest you

6. March 2025

salz21: Necessary Steps for the Future

On March 5, 2025, salz21 | Home of Innovation once again provided a platform for future topics, innovations, and interdisciplinary exchange. More than 1,000 visitors took the opportunity to learn about current developments and discuss perspectives for tomorrow. Three topics were particularly dominant: climate protection, artificial intelligence, and a strong Europe.

25. September 2024

Green Deal: How Sustainable Business Development Can Look

The EU aims to create political and legal frameworks through the Green Deal to transform both the economy and society in a sustainable way. The Pinzgau-based company Design Composite demonstrates how this can be implemented.

15. August 2024

Sunbeam Yachts: Where Craftsmanship Meets Digitalization

Sunbeam Yachts has been building exclusive sailing yachts at Mattsee for generations. The production is done by hand, with some processes now digitally supported.

12. August 2024

SBS: One Software for Many Self-Service Devices

As a leading provider of banking software in Salzburg, SBS is now exploring new markets. The company remains true to its core segment by offering manufacturer-neutral software for self-service devices in additional sectors.