Three innovative companies did not want to accept this state of affairs: the company MIKADO SMART ENGINEERING from East Tyrol, which is active in the aviation industry in the field of fixture construction, the milling company Moldtech Model and Mold Construction from Salzburg, and Karl Wagner with his former automotive supplier company Carbo Tech, joined forces to develop a new solution for the production of molds and models.

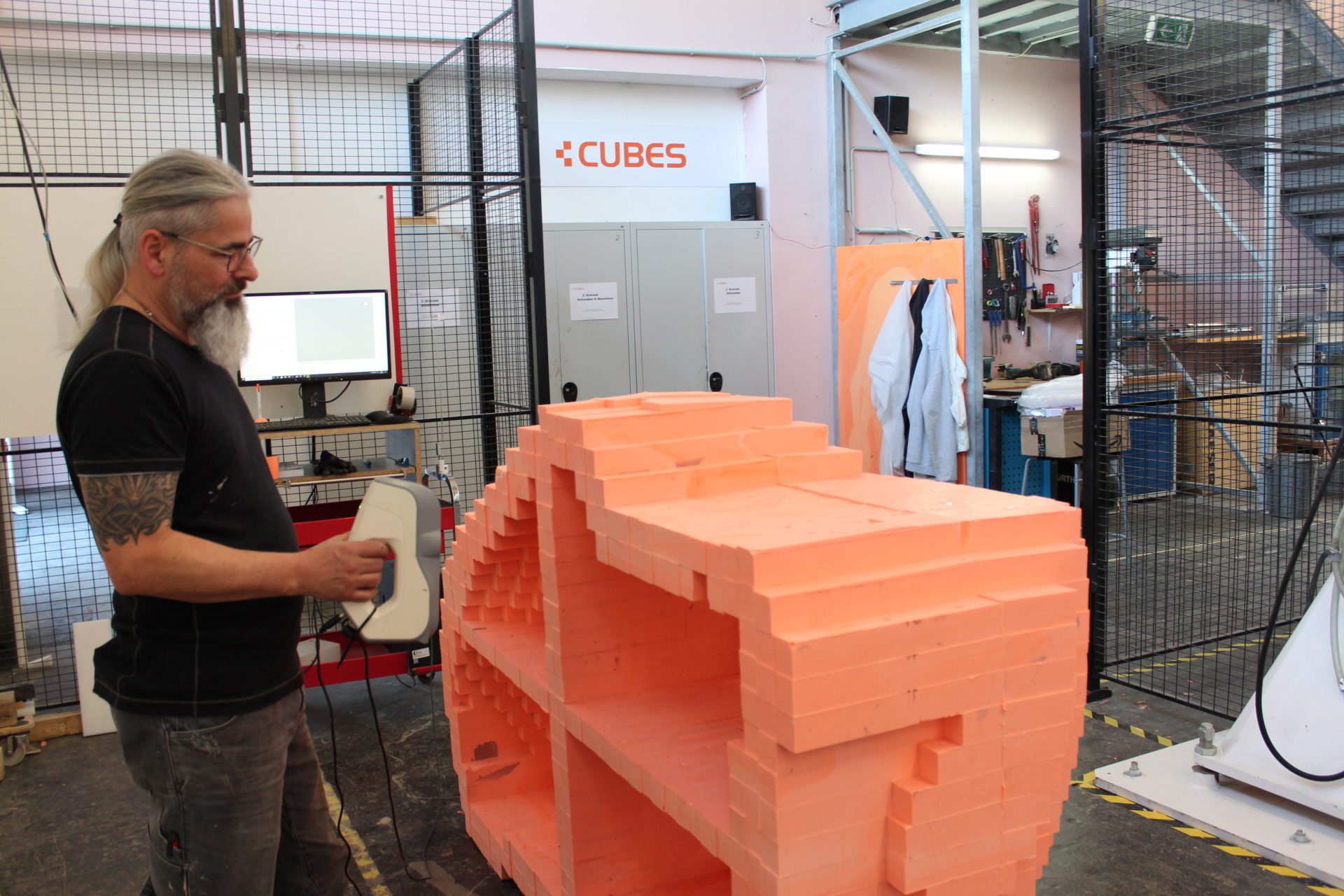

The idea was to build a shape-changing tool. After many development steps, a patented matrix tool from CUBES was created. The machine approaches the final shape with a grid. It positions 6,000 block elements automatically, so that any desired shape can be cast within the framework of 3x2x1.5m. CUBES’ customers can upload the desired shape to the specially developed software, which forwards the geometry to the machine.

The CUBES process offers several advantages. Unlike 3D printing, very large components can be produced. CUBES molds can measure several hundred liters, which a 3D printer cannot process. In addition, by approximating the contour to the final shape, the milling companies – CUBES’ direct customers – also save a lot of waste material. The mold is also cast in one piece, so there is no need to glue together various parts, as in other production processes. Customers save up to 40 percent on production costs. The entire process is faster, more efficient, cheaper, and environmentally friendly.

In the interview, Karl Wagner explains what it takes for innovation, how important the work environment is, and what role funding plays in innovation.

CUBES was awarded the Born Global Champion title last year. Additionally, in 2019, they won the State Award for Digitalization and second place at WIKARUS, the Salzburg Business Award. What do such awards mean to you?

It’s always a confirmation of what you’re doing. If you proclaim innovation, it’s of course nice when it’s visible to others as well. It’s simply confirmation that you’re not completely heading in the wrong direction. It’s especially nice for the employees. It’s a great signal to the market that you have been seen and achieved something special. And of course, everyone likes to be on stage and receive an award.

Do you see yourself as a game-changer?

I see myself as a technician. I am a technician with passion. That’s simply my thing. Basically, I see challenges and try to make them better somehow.

So you’re not satisfied with the status quo?

Definitely not. The engineer in me drives me to improve things and to develop something. If you’re lucky, the development also makes sense.

Is sustainability a big topic for you as a developer?

Yes, it’s a big topic. We all sit on the same planet and we have to treat it gently. But I’m convinced that this can also work without sacrifice. We create the same product for the customer with significantly less energy and material effort. That’s exactly innovation!

You must never see environmental protection as a job destroyer, but as a job creator. As a company, you just have to make sure that you are at the forefront. Then there are so many opportunities and possibilities. Once you’ve internalized a sustainable way of thinking, it’s really fun to be active in this area and make progress. Without sacrifice. That’s the art.

Innovation arises in people’s minds, machines or software are just results of that. – Karl Wagner, CUBES GmbH

So innovation is also a kind of attitude or mindset?

Yes, definitely.

How important are your employees for an innovative company?

The employees are everything. As CEO, I can set a direction and have ideas, but it’s the employees who implement the idea. It’s always the people in the company who carry innovation. Innovation arises in people’s minds, and the machines or software are the results of that.

What role do subsidies play in innovation?

Especially if you’re in mechanical engineering, you need money. And you need someone who has the money. The owners or investors have the money, which is difficult at the beginning, or they get it through subsidies. That’s why subsidies are immensely important. We are supported by Innovation Salzburg on this issue. Without a subsidy, we wouldn’t have been able to develop the machine, that has to be said. The subsidy advice works excellently in Salzburg. The infrastructure is excellent.

Is 3D printing a competitor for your technology?

To some extent, yes. At the beginning of the company’s founding, we asked ourselves whether we might eventually be replaced by 3D printing. But 3D printing has a few conceptual disadvantages. For one, it struggles with such large components. Our components can measure several hundred liters, and the 3D printer cannot process such material quantities. It would require a new 3D printing technology.

Furthermore, it requires a different material that solidifies or hardens very quickly. There are approaches to this with thermoplastics, i.e., with meltable plastics. However, these do not allow for arbitrarily large volumes because tensions arise during cooling. If you cut into it, the material warps because the tensions become free.

Therefore, we currently do not see a major competition with 3D printing. CUBES has created a completely new tool class and can thus serve all possible industrial applications around automobiles and airplanes.

To digital SalzburgThis might also interest you

11. November 2025

Eleven Million Euros for Five New Research Centers

Salzburg is investing in research: around eleven million euros from EU and state funds will go toward establishing five new research and transfer centers. They cover key future-oriented topics: artificial intelligence, climate protection, health, tourism, and data security.

24. October 2025

Christian Doppler Laboratory unites Artificial Intelligence and Image Processing in Salzburg

Salzburg is strengthening its cutting-edge research: In the new Christian Doppler Laboratory for the Authentication of Persons and Object Surfaces, innovative solutions for enhanced security are being developed by combining artificial intelligence and image processing. These solutions are created in close collaboration between science and industry.

4. June 2025

New Database for Commercial Properties and Sites in Salzburg

The new online platform www.standort-salzburg.at makes it easy to find available commercial properties, business premises, and brownfield sites across the entire province – all with just a few clicks.

6. March 2025

salz21: Necessary Steps for the Future

On March 5, 2025, salz21 | Home of Innovation once again provided a platform for future topics, innovations, and interdisciplinary exchange. More than 1,000 visitors took the opportunity to learn about current developments and discuss perspectives for tomorrow. Three topics were particularly dominant: climate protection, artificial intelligence, and a strong Europe.