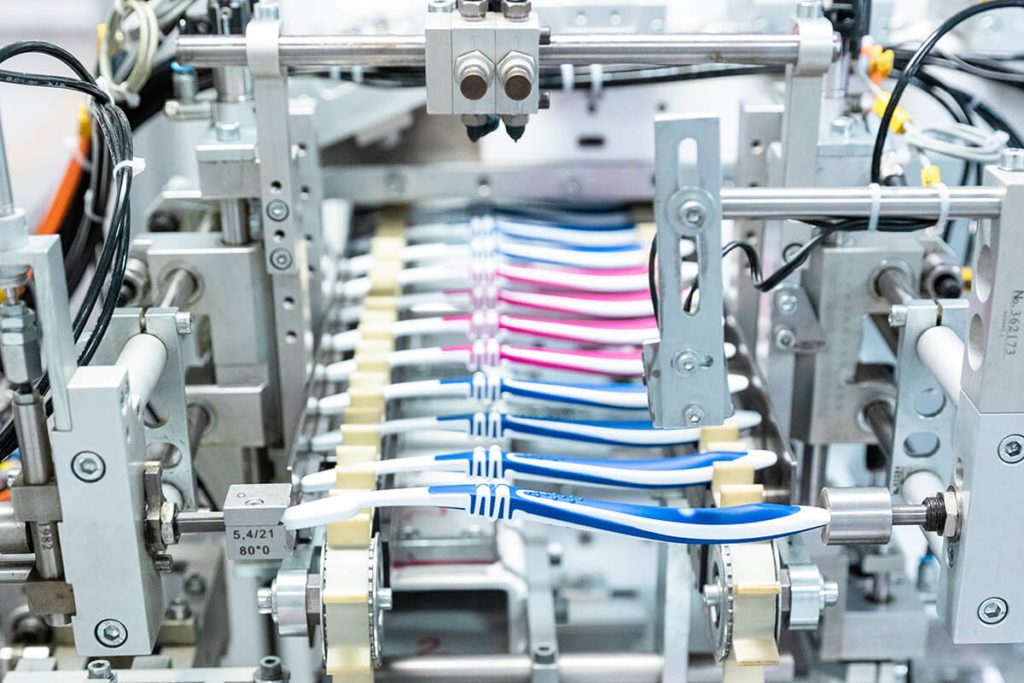

When you think of toothbrushes, you might think of oral hygiene, electric and manual toothbrushes, and bristle hardness. But who actually manufactures them and where? Many of the toothbrushes we use every day, in fact, have not traveled far: they are produced in Adnet. The company M+C Schiffer produces 35 million manual toothbrushes and 50 million injection-molded parts for brush heads of all well-known brands of electric toothbrushes every year.

Saving resources with circular economy

The company has now taken a step towards digitization with a project towards circular economy: toothbrush packaging has been switched from plastic to multiple recycled cardboard. “Our entire production should be more resource-efficient, and we ourselves want to work in a more resource-efficient way,” emphasizes CEO Karl Hofstätter, who has been running the business since 2017. An important aspect for him is also the relief of his employees.

New systems were installed on the production and packaging lines. These detect malfunctions faster and immediately report them to those responsible via smartphone. This way, the employees at the respective head stations have a better overview of the entire production. With the new system, for which the company has received three grants in the areas of circular economy and digitization, less waste is also produced. “We now have only 0.1 to 0.15 percent waste in injection molding instead of the usual one to two percent. This improvement is only possible through the more accurate monitoring of our production,” says Hofstätter.

Pandemic-induced upswing

The coronavirus crisis has brought the company an unexpected upswing. The largest production countries of toothbrushes, India and China, could no longer deliver their products cheaply to Europe. Due to the pandemic, transport from and to Asia became more expensive. “As a result, demand in Europe has increased, and we were able to increase our capacities,” reports Hofstätter. He emphasizes that “the best way to get a company out of a crisis is through innovation.”

About M+C Schiffer GmbH

- in Adnet in the Tennengau

- about 50 employees

- manufactures manual toothbrushes and injection molded parts for brush attachment heads

This might also interest you

5. August 2021

The toothbrush comes from Adnet

Many of the toothbrushes that we use daily are produced in Adnet by M+C Schiffer. The company has implemented projects towards digitalization and ecological sustainability, resulting in resource savings and relieving the workload of employees.

12. December 2021

Innovation Lab for the Education of the Future

The digitization has transformed the way we access information, and it has particularly influenced the way young people consume information. As a result, new approaches are needed to communicate socially relevant topics. The Innovation Lab for Education aims to test cooperative and interdisciplinary methods that can be integrated into schools to make them future-ready.

6. March 2025

salz21: Necessary Steps for the Future

On March 5, 2025, salz21 | Home of Innovation once again provided a platform for future topics, innovations, and interdisciplinary exchange. More than 1,000 visitors took the opportunity to learn about current developments and discuss perspectives for tomorrow. Three topics were particularly dominant: climate protection, artificial intelligence, and a strong Europe.

25. September 2024

Green Deal: How Sustainable Business Development Can Look

The EU aims to create political and legal frameworks through the Green Deal to transform both the economy and society in a sustainable way. The Pinzgau-based company Design Composite demonstrates how this can be implemented.